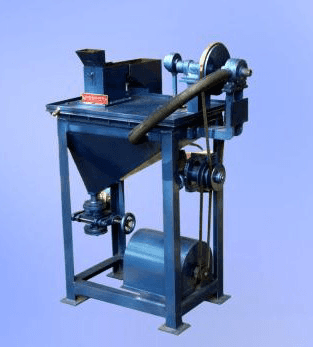

Mineral Jig

Our Products

Efficient gravity separation for high-grade mineral concentrates

A Mineral Jig is a simple yet effective mineral processing device that uses water and gravity to separate raw ore based on particle density. In heavy mineral mining, denser materials are the desired minerals, while lighter fractions are discarded as tailings. This process allows even low-grade ore streams to be upgraded to a saleable quality.

MPE’s Mineral Jigs are designed to treat unclassified feeds, producing a clean, high-grade concentrate. Effective separation relies on the differential settling rates of the solids, with feed sizes ranging from 1/4 inch to 1 inch.

These jigs are compact, dependable, and easy to operate, making them ideal for use in grinding circuits. They are engineered for durability, with few wearing parts that are easy to replace, ensuring long-term, trouble-free operation. MPE’s Mineral Jigs are field-proven, standard, and efficient, built to withstand the rigors of continuous processing.

Mineral Jigs are available in different sizes and configurations, including simplex and duplex compartments, to suit various processing requirements.

Customs built designs are also available.

Key Features

Available in multiple sizes with simplex or duplex chambers

Simple, dependable and rugged.

Sturdy welded tank.

Proven for many years in many applications.

Synchronised water valve controls admission to control suction stroke. Allows treatment of finer materials than conventional jigs.

Variation in stroke from 0 to ¾” easily obtained with adjustable eccentric.

Available Models & Capacities

|

|---|

Additional Equipment

We also manufacture a range of ancillary equipment, including hoppers, feeders, product launchers, slurry pumps, and centrifugal classifier feeders designed for seamless integration with our concentrating tables.

For specialized applications, MPE can supply Dross Separators (batch or continuous operation) for use alongside concentrating tables.

Frequently Asked Questions